|

SERVICES OFFERED:

Construction:

Demaco Corporation, is a full service construction company

and

maintains a cadre of highly experienced Field

Superintendents and Foremen in practically every

discipline of construction. With our skilled work crews,

you can count on having the best craftsmen working on

your job.

Maintenance:

The Plant Maintenance division of Demaco provides

the services of career maintenance workers, who

understand preventive maintenance, plant turnarounds,

replacement and repair of pumps, valves,

instrumentation, and other equipment. They can assist

you in the daily operation of your facility. We also

perform different testing options such as: Ultrasonic

testing, Holiday detector, and paint thickness testing.

Engineering:

Demaco

Engineers are capable to assume total responsibility for

fast-track and "turn-key" installations, when needed, or

can supplement your engineering personnel and function

as members of your Project Team.

Typical Work Performed:

Demaco provides general services and support

for maintenance and construction type work performed

throughout Puerto Rico. These services are offered

to every type of industry with a concentration in

pharmaceutical, oil refineries, and electrical power

plants. These quality services have been performed

for very satisfied customers. Listing to be

provided as per request.

Demaco

performs the following type of work:

-

Abrasive blasting

-

Corrosion control

-

Industrial

Painting

-

Crane and lifting operations

-

Demolition

-

Electrical work

-

Excavation and earth moving

-

Fire protection systems

-

Heavy equipment operations

-

Masonry

-

Fabrication &

Steel erection

-

Fiberglass work

-

Tank construction

& Inspection(API-653)

-

Pipeline construction

-

Tank insulating/coating

-

Welding and

metal cutting

-

Technical consultant

Outside of

its general maintenance, construction and engineering

competence, Demaco's specialty services also include

rubber linings for chemical tanks, chemical resistant

floor, thermoplastic welding and fabrication, chemical

brick laying, prefabricated plastic sumps and trenches,

piping, maintenance on pressure vessels and boilers,

sandblasting, painting for a wide array of protecting

coatings, and repair pumps, valves, instruments and

other equipment.

FACTORS THAT ENHANCE

DEMACO:

Personnel:

-

Core

technical staff with engineering backgrounds,

including professional engineers

-

Years

of experience recruiting a skilled, reliable, and

cost efficient labor

-

Highly

competitive hourly rates, administrative costs,

fringes, and other overhead expenses

-

Management professionals with broad experience in

refineries, petrochemical plants, and power plants

-

Spanish/English bilingual capabilities in office

staff and workforce

-

Skilled work crews for construction

-

Utilization of career maintenance workers for

preventive maintenance, plant turnarounds,

replacement and repair of pumps, valves,

instruments, and other equipment

-

Broad pool of trained, qualified labor resources

Areas of Expertise:

-

ASME qualified for manufacture and assembly of power

boilers and pressure vessels at plant locations and

field sites.

-

Licensed by American Petroleum Institute (API) for

tank inspection and certification.

-

Application of coatings and linings for tanks,

piping, pumps, trenches, and floors.

-

The

National Board of Boiler & Pressure Vessels

Inspectors Certification for Stamp "R" for Repairs

and/or Alterations of Boilers and Pressure Vessel

-

The

National Board of Boiler & Pressure Vessels

Inspectors Certification for Authorization.

Demaco is authorized to apply the "NB" and register

boilers, pressure vessel, or other pressure

retaining items with the National Board in

accordance with its provisions. The scope of

Authorization is limited to items manufactured in

accordance with ASME Stamps: "S" & "U"

-

The

American Society of Mechanical Engineers Certificate

of Authorization Certificate "S" for the Manufacture

and Assembly of Power Boilers

-

The

American Society of Mechanical Engineers Certificate

of Authorization Certificate "U" for the Manufacture

of Pressure Vessels

-

American Petroleum Institute API 653 Certification

for Tanks Inspection

-

Inspection and Repair of Propane Gas Cargo Tanks

(DOT Certified)

-

Member of Steel Structure Painting Council

(SSPC)

Facilities:

-

Outdoor

& Indoor storage areas are essentially unlimited,

secure, and guarded.

-

Comprehensive assortment of tools in broad size

ranges with secure tool room storage.

-

Largest fabrication shop in the southern region of

Puerto Rico, with sufficient space to handle

quantities of piping, construction materials, tools,

and equipment. 10 Ton Overhead Crane to facilitate

work within the fabrication shop.

Company Policies:

-

Quality Policy

-

Welders Quality Manual

-

Environmental Protection Policy

-

Alcohol and Drug Abuse Policy

-

Community Right to Know Policy

-

Workplace Violence/Sexual Harassment Policy

-

Disciplinary Actions Policy

Training:

-

In-house OSHA outreach

trainer with OTI-500 & OTI-501 credentials

-

10-30Hour OSHA

Outreach course in Construction and General Industry

-

Hazard Communications; HAZWOPER

-

Risk Management

-

Process Safety

Management

-

Job Safety/Hazard

Analysis

-

Heavy Equipment

Training and certification(Fork Lift, Cranes,

Trucks)

-

Welding and cutting

certifications

-

Six Sigma

DEMACO'S EXPERIENCE IN

POWER PLANTS:

Construction and installation of all off-site coded

pipelines required to operate Eco-Electrica Power Plant,

consisting of:

-

3.4 miles of 8" C.S. pipe for LPG from a nearby

storage plant (ProCaribe) to Eco-Electrica,

including a below-grade river crossing

-

1.1 miles of 24" API - 5L X 60 pipes and 0.7 miles

of 20" API - 5L X 60 to South Coast Power Plant for

LNG

-

3,500 L.F. of 8" C.S pipe for fuel oil running from

former UCC Dock to Eco-Electrica

-

2

miles of 8" type 304 stainless steel pipe from

Desalinated Water Plant to South Coast Power Plant.

-

2

miles of 10" cement lined C.S. pipe for potable

water from Eco-Electrica to Puerto Rico Aqueduct and

Sewer Authority (PRASA) connecting point.

Construction of 230 KV Transmission Line Foundations in

Eco Electrica Which Included:

-

29(each) concrete structures for giant transmission

towers

-

Piles-driving for all structures

-

Demolition of some existing structures on the way

Provide all Labor, Supervision and Management to Install

all Equipment and all Plant Associated Piping in Eco Electrica such as:

-

All sizes of bore piping.

-

Carbon steel, alloy and stainless steel piping.

-

Set in place, align and grout of all equipment,

including rotary.

-

All structures, hangers and supports as required.

DEMACO'S EXPERIENCE IN

BOILERS AND PRESSURE VESSELS:

-

Repairs to boiler Cleaver Brooks 250 HP - Rico, Las

Piedras, PR

-

Repairs and modifications to Economizer Vent Piping

at HRSG #2, Eco Electrica, Pe˝uelas, PR

-

Repair 12" id - 150# nozzle cracked weld. Remove,

weld, and reinstall nozzle on top head of reactor at

110, BASF, Manati, PR

-

Remove and reinstall two 3 ft. long pieces of pipe

at HRSG #1 at Eco Electrica, Pe˝uelas, PR

-

Repair DS-1 Desuper Heater at HRSG #1 at Eco

Electrica, Pe˝uelas, PR

DEMACO'S EXPERIENCE IN

CORROSION CONTROL:

-

Demaco has a vast experience in the removal and

replacement of protective coatings in retaining dikes,

ponds, and floors in sulfuric acid, caustic, and

hydrochloric acid service

-

Concrete floor repair and installation of protective

coatings

-

Rubber lining on storage tanks of all sizes

.jpeg)

.jpeg) .jpeg)

.jpeg) .jpeg)

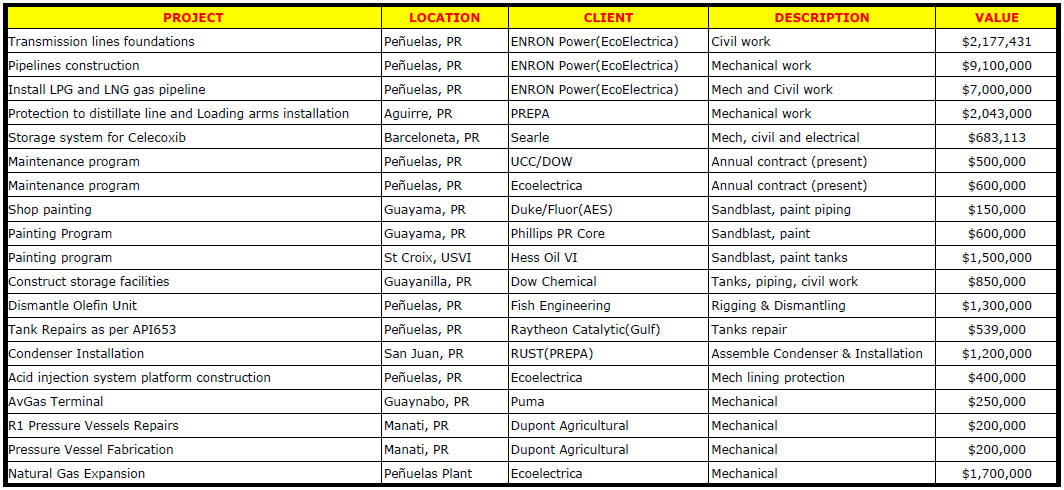

EXAMPLES OF DEMACO PROJECTS:

Up

ALL RIGHTS

RESERVED @ DEMACO CORP. 2022

|