|

Demaco Terminal Operations is a "terminal for

hire". We receive, store and dispatch chemical

products for world known chemical companies. We do not own the products

stored at our facility, but we are responsible for

maintaining the quality and quantity of the products

while under our custody.

Typical Work Performed:

ELECTRICAL POWER:

Electric power is purchased from PR Electric Power

Authority at 115 KV.

Two incoming transmission lines supply power

to the plant switchyard.

Switches and oil circuit breakers in the

switchyard are arranged to feed 115 KV into one 20

MVA transformer supplying power to the main 13.8KV

distribution system.

Power is also distributed at 2.4 KV and at

480 volts.

FIRE PROTECTION WATER:

A deep well in our facility pumps water into the

firewater pond, where two(2) 2,500 gpm pumps provide

water for the fire protection water system located throughout the

Terminal and dock facilities.

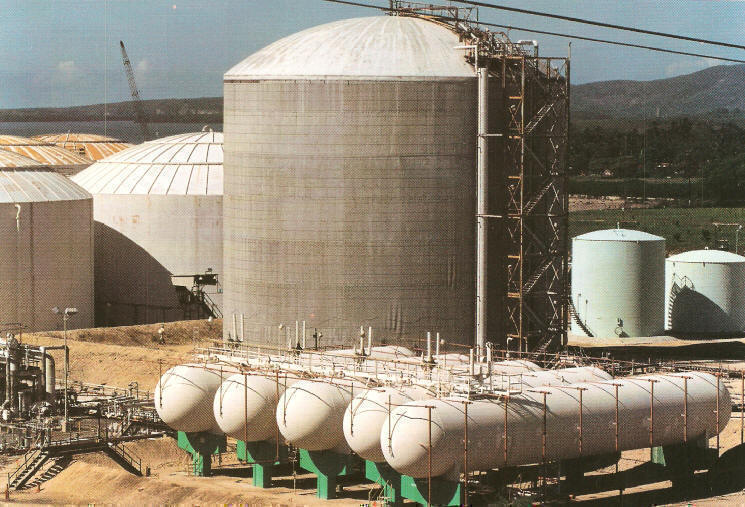

STORAGE TANKS:

There are 34 tanks in the farm with a total capacity of

26,265,662 gallons or 625,816 bbls. All tanks are carbon

steel. There are 7 pressure vessels.

The regular tanks in VOC's service have internal

floating roofs.

|

Storage

Capacity |

Number

of

Tanks |

Range

Tanks |

Modes

Served |

Truck

Facilities |

Commodities

Handled |

26,265,662

|

34

Tanks |

7,000

4,000,000 |

Tanker

Barge |

One Truck

Scale

/

Three Loading Racks |

Acetone

Heptane

Hexane

Isopropanol

Methanol

Petroleum Distillates

Sodium Hydroxide

Toluene |

PIPELINE SYSTEM:

DOCK

FACILITY:

The dock is leased from the Ports

Authority.

The dock accommodates tanker vessels up

to 800 ft. in length.

The pier consists of a 10 ft. wide

trestle from shore to the main breasting

dolphin, two auxiliary breasting dolphins, two

mooring dolphins, a walkway, and an outboard

dolphin.

The pier simultaneously accommodates two liquid

product transfers.

Demaco utilizes the east side of the

dock; a neighboring company utilizes the west side.

The main breasting dolphin is a

cast-in-place monolithic concrete structure with

fendering on both sides.

It is supported by on pipe piles filled

with concrete.

The liquid unloading facilities consist

of a structure to handle the hoses.

Product and service piping (water and

nitrogen) terminate on the main breasting

dolphin.

Harbor: A

300 ft. wide approach channel 40 ft. in depth

was dredged in Guayanilla Bay to the marine

facility.

The dredged area increases to 380 ft. wide in

the vicinity of the pier.

Potential Uses:

-

Development of a Terminal to handle storage for

pharmaceuticals and other plants.

-

Distribution center for utilities, materials or

construction materials.

-

Development of a free-trade zone for tax-free

industries.

-

Storage of Cryogenics material.

-

Development of manufacturing areas such as:

Pharmaceutical Industries, or military components

for aircraft industries.

-

Drum manufacturing and drumming processing.

-

Assembly line for internal combustion engines.

-

Assembly line for agricultural machinery components.

-

Assembly line for automobiles.

-

Manufacture of houseware goods, such as, stainless

steel pots, plastic containers, etc.

-

Manufacture of rubber tires(Uniroyal, B.F. Goodrich,

or others).

-

Toy

manufacturing.

-

Waste Treatment Plant incineration.

-

Service Industries as a finish processing zone for

process which manufacturing has been started in the

Caribbean or Latin American countries.

-

Research and development Laboratories.

Up

ALL RIGHTS

RESERVED @ DEMACO CORP. 2022 |